- Home Page

- Company Profile

-

Our Products

- Paper Edge Protector Machine

- High Speed Paper slitter and rewinder PLC

- Paper Slitter and Rewinder Machine

- Paper Angle Board Forming Machine

- Paper Edge Protector Machine with Punching Device

- CNC Paper Corner Protector Machine

- Automatic Paper Protector Cutter Machine

- High Speed Paper Edge Protector Machine

- Paper Edge Protector Machine

- CNC paper edge board machine with online punching device

- PLC controlled paper angle board machine with online punching device

- High speed CNC paper edge board machine with online punching device

- Multi-function paper edge protector machine for V profile U profile and flat board production

- Paper slitting and rewinding machine PLC

- Paper Tube And Bag Machine

- Spiral paper tube machine with large diameter up to 500mm

- Paper Bag Machine

- Paper Tube Machine

- Square Paper Tube Machine

- Parallel Paper Stick Making Machine

- Spiral Paper Stick Making Machine for Lollipop

- Paper Straw Making Machine

- Spiral paper tube machine with large capacity

- paper stick making machine

- High speed CNC paper tube machine

- Paper Honeycomb Machine

- Automatic Honeycomb Paper Core Production Line

- Wrap Honeycomb Paper Making Machines

- Automatic Paper Honeycomb Core Making Machine

- Fully automatic paper honeycomb panel production line

- Fully automatic paper honeycomb core and panel production line

- Paper honeycomb panel lamiantion machine

- Paper honeycomb wrap die cutting machine

- Paper Laminating Machine And Production Line

- Paper Corrugating Machine

- Hot Melt Labeling Machine

- Paper Egg Tray Forming Machine

- Paper Packaging Material

- Woodworking Machine

- Paper Edge Protector Machine

- Vidoes

- Downloads Documents

- Contact Us

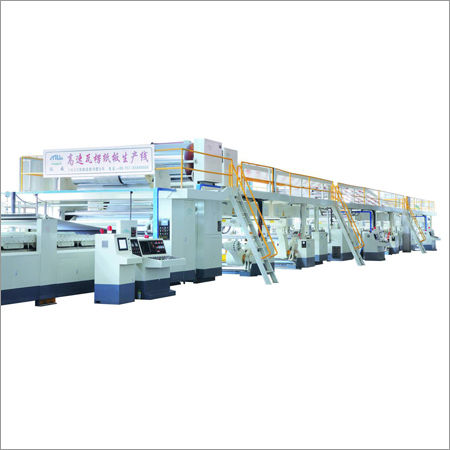

Printer Dryer Die Cutter Machine

X

Printer Dryer Die Cutter Machine Price And Quantity

- 1 Set

- 50000.00 - 80000.00 USD ($)

- 50000 USD ($)

Product Description

The Printer Dryer Die Cutter Machine is a precision engineered machine. That is used for cutting various types of dyes. They are made using optimal grade materials and cutting edge technology in accordance with set industry norms. The Printer Dryer Die Cutter Machine is widely used for cutting paper and corrugated sheets. Further, they are checked by our quality assurance team on numerous parameters before dispatching to customers. These machines finds their usage in paper industries and are known for their features such as high operational fluency, user-friendly applications and low maintenance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email