- Home Page

- Company Profile

-

Our Products

- Paper Edge Protector Machine

- High Speed Paper slitter and rewinder PLC

- Paper Slitter and Rewinder Machine

- Paper Angle Board Forming Machine

- Paper Edge Protector Machine with Punching Device

- CNC Paper Corner Protector Machine

- Automatic Paper Protector Cutter Machine

- High Speed Paper Edge Protector Machine

- Paper Edge Protector Machine

- CNC paper edge board machine with online punching device

- PLC controlled paper angle board machine with online punching device

- High speed CNC paper edge board machine with online punching device

- Multi-function paper edge protector machine for V profile U profile and flat board production

- Paper slitting and rewinding machine PLC

- Paper Tube And Bag Machine

- Spiral paper tube machine with large diameter up to 500mm

- Paper Bag Machine

- Paper Tube Machine

- Square Paper Tube Machine

- Parallel Paper Stick Making Machine

- Spiral Paper Stick Making Machine for Lollipop

- Paper Straw Making Machine

- Spiral paper tube machine with large capacity

- paper stick making machine

- High speed CNC paper tube machine

- Paper Honeycomb Machine

- Automatic Honeycomb Paper Core Production Line

- Wrap Honeycomb Paper Making Machines

- Automatic Paper Honeycomb Core Making Machine

- Fully automatic paper honeycomb panel production line

- Fully automatic paper honeycomb core and panel production line

- Paper honeycomb panel lamiantion machine

- Paper honeycomb wrap die cutting machine

- Paper Laminating Machine And Production Line

- Paper Corrugating Machine

- Hot Melt Labeling Machine

- Paper Egg Tray Forming Machine

- Paper Packaging Material

- Woodworking Machine

- Paper Edge Protector Machine

- Vidoes

- Downloads Documents

- Contact Us

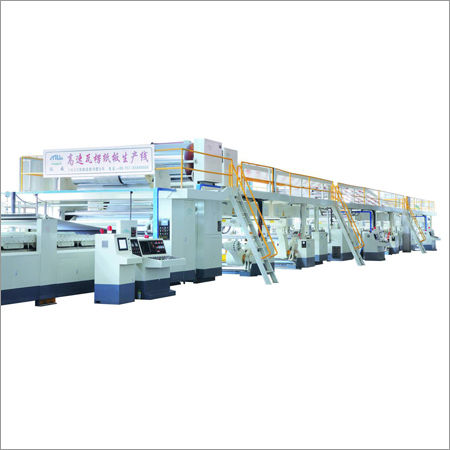

Printer Dryer Die Cutter Machine

Product Details:

- Grade Industrial Grade

- Type Automatic

- Material Mild Steel

- Capacity High Volume (Industrial)

- Computerized Yes

- Control System PLC Touch Screen

- Cutting Speed 2000-6000 sheets/hour

50000 USD ($)

X

Printer Dryer Die Cutter Machine Price And Quantity

- 50000.00 - 80000.00 USD ($)

- 1 Set

- 50000 USD ($)

- Corrugated Board, Cardboard, Duplex Paper

- Automatic Centralized Lubrication

- Automatic Sheet Feeding

- Infrared Dryer Integrated

- Export Wooden Case

- 0.8 MPa, 200 L/min

- Air Cooling

- 6000 x 2500 mm

- Emergency Stop, Overload Protection

- 250 Tons

- 7-inch Color Touch Screen

- Single/Double Color Flexo Printing Option

- 84 dB

- 1200 mm

Printer Dryer Die Cutter Machine Product Specifications

- Blue and White

- 380V / 50Hz

- 5300 x 2100 x 2200 mm

- 1400 x 1200 mm (Max), 480 x 370 mm (Min)

- Automatic

- Mild Steel

- 2-10 mm

- Yes

- Approx. 6500 kg

- 2000-6000 sheets/hour

- PLC Touch Screen

- 11 kW

- Industrial Grade

- High Volume (Industrial)

- Corrugated Board, Cardboard, Duplex Paper

- Automatic Centralized Lubrication

- Automatic Sheet Feeding

- Infrared Dryer Integrated

- Export Wooden Case

- 0.8 MPa, 200 L/min

- Air Cooling

- 6000 x 2500 mm

- Emergency Stop, Overload Protection

- 250 Tons

- 7-inch Color Touch Screen

- Single/Double Color Flexo Printing Option

- 84 dB

- 1200 mm

Product Description

The Printer Dryer Die Cutter Machine is a precision engineered machine. That is used for cutting various types of dyes. They are made using optimal grade materials and cutting edge technology in accordance with set industry norms. The Printer Dryer Die Cutter Machine is widely used for cutting paper and corrugated sheets. Further, they are checked by our quality assurance team on numerous parameters before dispatching to customers. These machines finds their usage in paper industries and are known for their features such as high operational fluency, user-friendly applications and low maintenance.

High-Performance Automation

Engineered for efficiency, this machine boasts automatic sheet feeding and an operating speed of up to 6000 sheets per hour. Its air-cooled system, centralized lubrication, and computerized PLC controls deliver consistent reliability with minimal operator intervention.

Safety and Operator-Friendly Design

Safety is paramount. The machine is equipped with emergency stop and overload protection features, while its low operating noise level (84 dB) provides a better working environment. The intuitive 7-inch touch screen simplifies operation for users.

Versatility and Industrial Capability

Accommodating materials like corrugated board, cardboard, and duplex paper, the machines robust die-cutting pressure and adjustable cutting sizes make it suitable for a range of packaging and printing applications. Its high capacity, industrial-grade build, and precision outputs ensure top-tier performance.

FAQs of Printer Dryer Die Cutter Machine:

Q: How does the automatic feeding system work in the Printer Dryer Die Cutter Machine?

A: The machine uses an advanced automatic sheet feeding system that reliably loads materials such as corrugated board, cardboard, or duplex paper into the processing section. This automation enables continuous operation, reducing manual handling and boosting productivity.Q: What materials are suitable for use with this die cutter machine?

A: This machine is designed to process a variety of materials including corrugated board, cardboard, and duplex paper, making it highly suitable for packaging manufacturers and printers seeking flexibility in material choices.Q: When should I use the emergency stop or overload protection features?

A: The emergency stop should be activated immediately if a hazardous situation or equipment malfunction occurs. The overload protection automatically engages if the machine detects excessive pressure or load, helping to prevent mechanical damage and ensuring operator safety.Q: Where can this machine be installed, and how much space is required?

A: To ensure proper installation, the machine requires a dedicated space measuring at least 6000 x 2500 mm. This provides sufficient room for operation, maintenance, and safe material handling in an industrial setting.Q: What is the typical process for setting up and operating the machine?

A: Setting up involves connecting the machine to the required power supply (380V / 50Hz, 11 kW), ensuring air supply (0.8 MPa, 200 L/min), and configuring the PLC touch screen for your job requirements. Load the desired materials, set print and die-cut parameters, and start automated production.Q: How does the integrated infrared dryer benefit the production process?

A: The infrared dryer, integrated within the unit, accelerates ink drying on printed sheets, allowing for higher speeds and immediate downstream processing. This integration minimizes production delays and enhances overall throughput.Q: What is the maximum cutting size, and how thick can the materials be?

A: The machine can handle sheet sizes up to 1400 x 1200 mm, with thicknesses ranging from 2 to 10 mm. This accommodates a wide spectrum of packaging formats and requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email